photos and words by Dersu Rhodes

Branding yourself can be a daunting task. For me, it’s taken years to finally sit down and design a type mark for myself, create an identity, and get business cards printed. Since I have moved to Venice, I promised myself that I would collaborate with the people around me in this new neighborhood and hearing about Sue Kaplan and The Garlow Studio from a friend, I reached out to her about printing my cards.

I spend days in front of a screen, and the closest I get to hands on, is tapping on a keyboard or holding a Wacom pen. To be able to go and print at a letterpress shop and to be as hands on as printing gets, was such an exciting opportunity. Sue is a hipster, not in her own eyes, but rather in the way we define “hipsters”. She not only prints out of the back of her shop, but she sips Cortado’s made fresh from her machine in the back, she imports beans from Italy, and she wears spectacles (but these ones are actually prescription lenses unlike some hipsters I know).

To be in the shop, to see her mix the ink, to apply it to the rollers, and then to set and adjust the die is an experience far beyond any digital printer can provide. As I watch her feed the sheets of paper into the old Vandercook press and see my artwork pressed into the surface, I feel more satisfied than I have been in a long time. Perhaps it’s because I am learning about a craft that has mostly been forgotten, or perhaps it is because I am in the presence of such a kind and dedicated spirit, or maybe it’s because I am celebrating the printing of my cards, and the completion of a project a long time in the making.

Words from Sue Kaplan on the printing of the cards

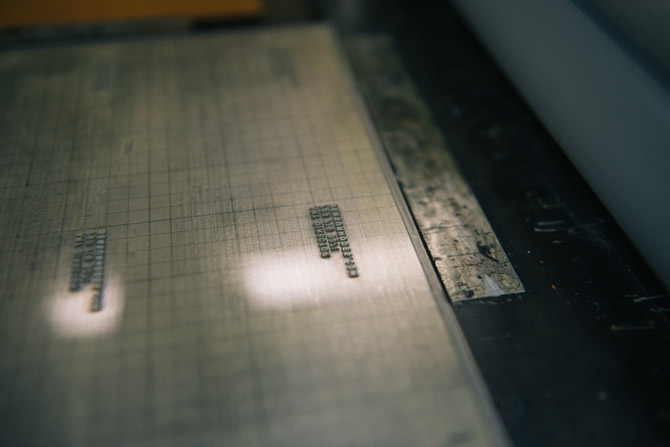

It was a pleasure to print Dersu’s cards. He instinctively understood what letterpress does best: simple, clear type well organized on the page. We worked with photopolymer plates. Theses are actually plastic plates that are processed to form a type-high printing surface. Because one designs on the computer, you can have much more flexibility as to design and range of typefaces in your printed piece.

The plastic plate is placed on an aluminum base that brings it up to the printing height of metal type. I used a Vandercook proof press, a hand operated cylinder press. First one inks the type by rolling the cylinder with the ink roller down the type. Then the paper runs around the cylinder meeting the type as one rolls it down the press bed. There are many things one needs to check to get a good print: roller height, amount of ink, packing and of course, that the plate displaced on the base and in the bed of the press exactly as one wants it on the paper.

Dersu was very particular about the color (we mixed in a little grey to an opaque white) he wanted and printed on the Lettra pearly white paper, it just worked perfectly.

The finished product. Photo by Christoffer Meyer